Our own SIHARD brand includes cold-work tool steels.

The SIHARD brand steels are adapted for machining and cutting metal, wood and synthetic materials and have the characteristics of dimensional stability, high compressive strength and the required toughness, considering their intended use. The adjusted chemical composition and processing technology provides SIHARD brand steel with the necessary resistance to adhesion, abrasion, cut-edge fragmentation, the possibility of nitration, hard PVD and EDM coatings.

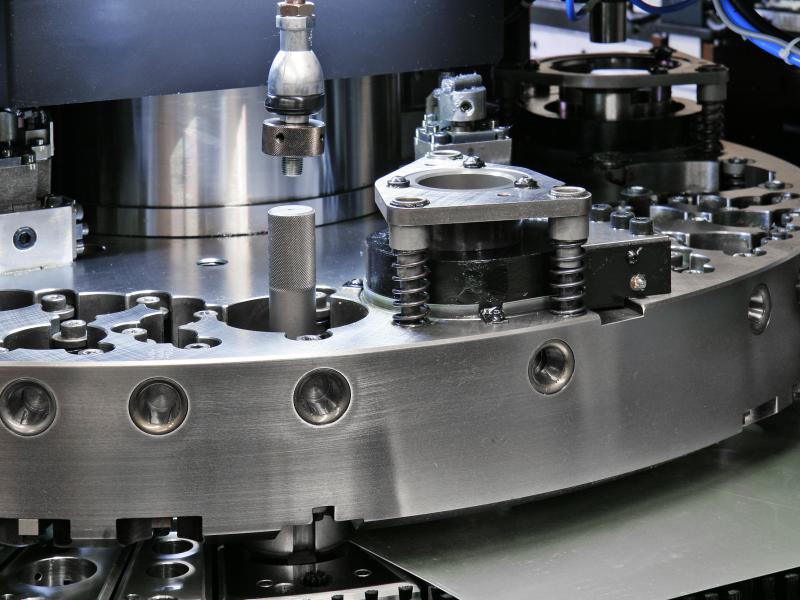

SIHARD brand steels are used for cyclically loaded tools such as: punchers, pressers, die inserts for the compaction of powders, knives/blades, forging, rolling and deep drawing tools. Tool steel is normally delivered in a soft-annealed condition.

Conversion, cutting metal, wood, plastic and other materials, and precision tools are the primary sectors for SIHARD steel applications. We produce steel for all special processes. This steel provides high wear resistance and ensures a long tool life.

A wide range of tool steels, from low-alloy steel suitable for simpler applications to high alloy and specially developed high strength SIHARD brand steels for the most demanding applications, allows us to combine our knowledge and experience in all relevant fields. Steel whose origin is known, with high wear resistance provided by our production process, allows us to meet and exceed the expectations of our customers and users of our SIHARD brand steel.

The main characteristics of our cold-work tool steel under SIHARD brand steel:

- High compressive strength

- Dimensional stability

- High isotropy

- Cracking resistance

- Good hardenability

- Repeatable mechanical treatment in good condition

- Repeatable behaviour of tools in use

Heat Treatment

Heat treatment carried out in open air, oil or by vacuum hardening technology . The heat treatment selected depends on tool complexity and the grade of SIHARD steel.

| W. NR. | C | Si | Mn | Mo | Ni | V | W | ||

|---|---|---|---|---|---|---|---|---|---|

| SIHARD 2316 | 1.4122 | 0,39 | max 1,0 | max 1,50 | 1,05 | max 1,0 | / | / | 49 HRC |

| SIHARD 2357 | 1.2357 | 0,5 | 0,3 | 0,6 | 1,5 | / | 0,2 | / | 59-61 HRC |

| SIHARD 2363 | 1.2363 | 1 | 0,3 | 0,55 | 1,05 | / | 0,2 | / | 63 HRC |

| SIHARD 2379 | 1.2379 | 1,55 | 0,25 | 0,3 | 0,7 | / | 1 | / | 62-64 HRC |

| SIHARD 2310 | 1.2510 | 0,95 | 0,25 | 1,1 | / | / | 0,1 | 0,6 | 64 HRC |

| SIHARD 2331 | 1.2631 | 0,5 | 0,9 | 0,5 | 8,5 | / | / | 1,25 | / |

| SIHARD 2367 | 1.2767 | 0,45 | 0,25 | 0,3 | 1,35 | 4 | / | / | 56 HRC |

| SIHARD 2342 | 1.2842 | 0,9 | 0,25 | 2 | / | / | 0,1 | / | 63-65 HRC |